The boiler house is a former power station located in Moss Side, Manchester. In the 1990s it functioned as a power station for thousands of homes, and since

Group 01

MYCO-POD

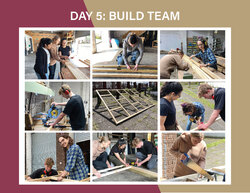

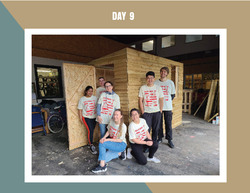

The boiler house is a center to bring together a community through the hosting of free workshops and low-cost workshop spaces. Workshops include woodworking and mycelium growing as a way of teaching new hands-on skills to the community. Mycelium is the root network of mushrooms and can be used in architecture as an insulator and as a structural material. In the future, the Boiler House strives to fit their building with mycelium insulation, a carbon-negative product. For the past few weeks, they have been growing mycelium insulation for us to design a sitting pod to fill with this locally-grown insulation. This pod will educate the public and funders about the power of mycelium while providing a usable seat to experience the insulative and acoustic dampening effects. The pod will also house research about how mycelium is grown, how it can be used as insulation, and how effective it is. The work we do will help contribute to the research and funding needed to make their unheated hangar space usable in the colder months. Our project aims to provide a product for the Boiler House that showcases their workshop facilities, mycelium growing initiative, and helps get funding to insulate their building. During the two weeks you spend with our team you will get to partake in a physical build and research a new carbon-negative, sustainable material.

Lauren Lok-Men N / Mary D / Ugne B / Binyang Z / Holly W