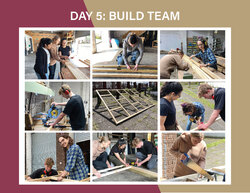

Day 5: BUILD TEAM

Today is the first day of construction. We first started with constructing the walls of the eco-shed. To start we cut down materials to create a timber frame structure. We divided ourselves into two teams: one for data measurement and the other for cutting the timber. The two groups worked alternated tasks so that each person could experience the whole building process. During the measuring process we had woodshop staff, Steve and Nick, guide us on how to use different tools. They taught us different techniques for marking measurements with a string line to improve efficiency and accuracy. During the cutting process, the team had more opportunities to practice using the chop saw.

The cut timber cannot be used directly for assembly, it also needs to be treated by soaking each end into the preserving liquid for 10 mins. After that, the timbers were ready to be assembled. During the fitting process, Lad gave us a master class on how to best use a drill. While it appears easy, it was a challenge to get good at using one. With the help of Steve and Nick we were taught how to make the the timber members fit tighter and without gaps. It is also worth talking about that fitting the side walls was a difficult task as it had a sloping frame at the top and required the posts and top frame to be cut at an angle. This needed to be done with a hand saw. With Steve and Nick demonstrating and guiding us, we quickly learnt how to use the hand saw and the tricks to use it.

After a day's work, we completed all the wall framing for the eco-shed. Thanks to Steve and Nick sharing, we also learnt a lot about woodworking in the process. It was a tough process, but everyone in the team was very committed and enthusiastic. There was a sense of pride in each member as they watched the final four sides of the solid and neatly finished frame. Tomorrow we will get a delivery of the rest of our materials and develop the ecoshed much further!

Today is the first day of construction. We first started with constructing the walls of the eco-shed. To start we cut down materials to create a timber frame structure. We divided ourselves into two teams: one for data measurement and the other for cutting the timber. The two groups worked alternated tasks so that each person could experience the whole building process. During the measuring process we had woodshop staff, Steve and Nick, guide us on how to use different tools. They taught us different techniques for marking measurements with a string line to improve efficiency and accuracy. During the cutting process, the team had more opportunities to practice using the chop saw.

The cut timber cannot be used directly for assembly, it also needs to be treated by soaking each end into the preserving liquid for 10 mins. After that, the timbers were ready to be assembled. During the fitting process, Lad gave us a master class on how to best use a drill. While it appears easy, it was a challenge to get good at using one. With the help of Steve and Nick we were taught how to make the the timber members fit tighter and without gaps. It is also worth talking about that fitting the side walls was a difficult task as it had a sloping frame at the top and required the posts and top frame to be cut at an angle. This needed to be done with a hand saw. With Steve and Nick demonstrating and guiding us, we quickly learnt how to use the hand saw and the tricks to use it.

After a day's work, we completed all the wall framing for the eco-shed. Thanks to Steve and Nick sharing, we also learnt a lot about woodworking in the process. It was a tough process, but everyone in the team was very committed and enthusiastic. There was a sense of pride in each member as they watched the final four sides of the solid and neatly finished frame. Tomorrow we will get a delivery of the rest of our materials and develop the ecoshed much further!

Posted 16 May 2023 05:33